Tips for Improving Warehouse Efficiency

Warehouse efficiency is strongly linked with the warehouse’s security. It’s not only about doing things faster or more organized, but always considering employees’ security.

Improving warehouse efficiency guarantees that the enterprise doesn’t lose money and credibility, while it becomes a place where workers feel appreciated and good at what they do, and a sense of community develops.

Since your warehouse is the heart of your business, increasing productivity and maximizing operations may be a topic you’re interested in, so let’s mention 5 warehouse efficiency tips that come in handy.

Optimize Available Space

Yes, this is a straightforward tip but often forgotten. Optimizing your warehouse’s space means understanding different warehouse types and correctly using the vertical space available with the right storage units and equipment to pick and store the material.

Another typical mistake is using the same racks in the entire warehouse. There are at least 20 different types of racks. For example, pushback racks provide 2-6 deep storage, which is great for saving space, but lanes must be emptied to maintain a proper product rotation.

If you choose to use racks that are high up, make sure to invest in a lift like the ballymore lifts on the Platforms And Ladders website.

We have found out that workstations also need to be distributed efficiently; if the packaging workstation does not have enough space or access to the packaging materials, the process will slow down. The deliveries will arrive late. We recommend using the 5S method to organize better workstations: sort, set in order, shine, standardize, and sustain. Optimize your space wisely, and watch how warehouse efficiency boosts in a short time.

Organization Before Anything Else

It is essential for your warehouse’s efficiency levels that everybody knows where everything is and how to access any area if permitted. When your warehouse’s space is well distributed, enough space is left for all kinds of employees to process their tasks more efficiently.

So they can avoid stepping on each other, misplacing products, or going to the opposite of where they are supposed to be. For safety reasons, every workstation must be organized at all times (even when there’s no employee there) and should have standardized manuals and rules of operation.

Communication Between Departments

We are talking about something more than a weekly newsletter. Team managers need to organize weekly meetings to share each department’s performance, KPIs, needs, and improvement proposals.

Everybody must know how other departments work; otherwise, slight changes in the process can affect other departments’ performance, compromising the entire cargo. And of course, employees not participating in those meetings also must be informed of what’s decided and commented there.

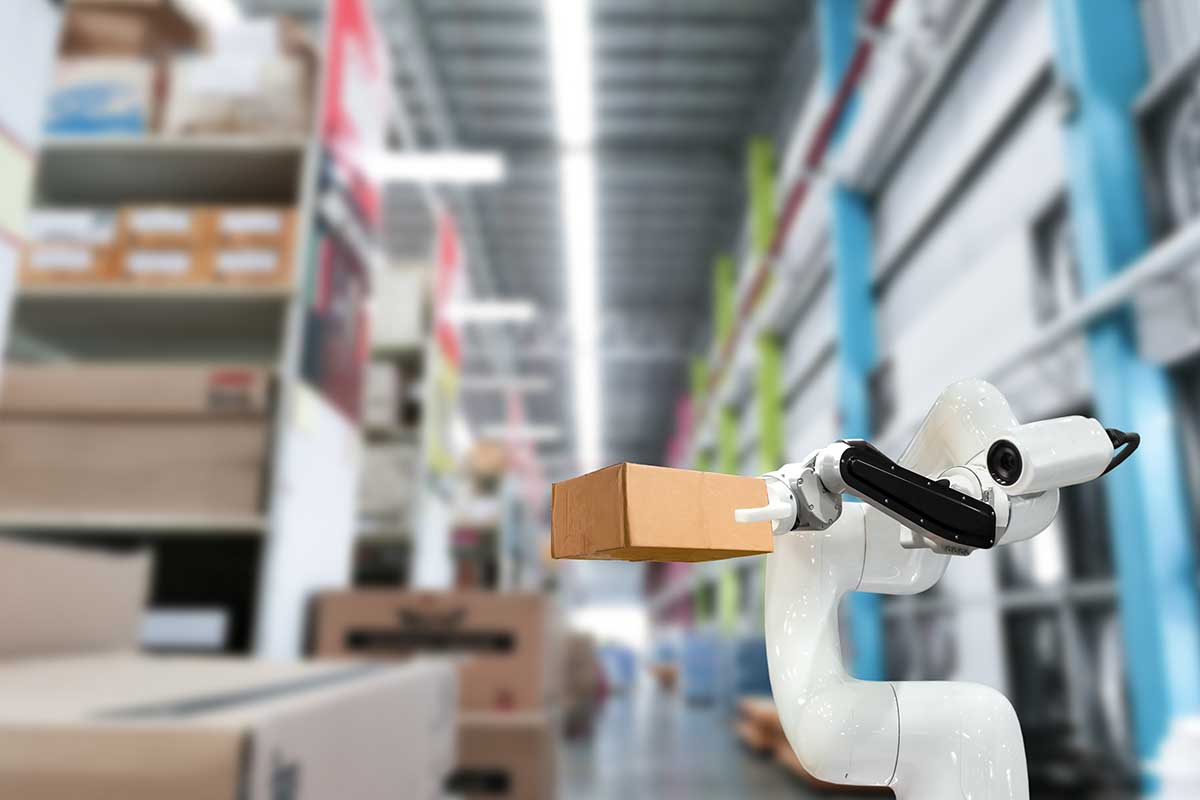

Technology Is Your New Friend

Nowadays, it’s impossible to properly handle a warehouse of any size without warehouse inventory management software. Well, maybe not impossible, but it will certainly be a tough task that will demand a lot of time, money, and human resources.

To be updated on industrial machinery, warehouse efficiency tips, and technology news, you can read Industrial Products Purchase. An easy way to know what may be needed in your warehouse in terms of technology is by reading blogs related to this field, and of course, conducting tests.

Improving warehouse efficiency means having technology as your new friend, automatize everything that can be automatized, and keep track of everything through your phone, laptop, or tablet, in or out of the warehouse.

Fast-Moving Products? Make Them a Priority

More and more companies are joining the 1-day shipping trend, so finding this product, pack it on time, and deliver it precisely on time are tasks that can get complicated if the products are not easy to reach and visible enough to reach it.

Having trucks coming and going all day, people walking from one part of the warehouse to another, and employees working in rotating stations can create a real hassle when it comes to fast-moving products.

Prioritizing this kind of shipment and putting it in a visible and easy to access part of the warehouse guarantees that employees can find them quickly and pack them in a short time to ensure the package was sent on time. Go over your inventory and determine which products are often labeled as fast-moving, and train your employees to handle them properly.

Improving Warehouse Efficiency

We selected these warehouse efficiency tips because they are often forgotten by managers and team leaders and believe they are functional and adaptable to almost any kind of warehouse in the country. To successfully find out how to begin improving warehouse efficiency, we recommend running A/B tests often to see which tasks may need some improvements, why they are not working out as expected, and how to change them efficiently.

Remember that changing one little thing in the chain of work will inevitably change one or many others, even they belong to different processes. That’s why communication will be a valuable skill for your team. When everybody knows what is being done properly and what is not, more proper changes can be adopted.

Apply these warehouse efficiency tips after your A/B test and watch your efficiency levels go as high as you have always dreamed of.