4 Heavy Machinery Maintenance Tips to Extend Longevity

Heavy machines are a crucial part of many industries, but they require regular maintenance to function correctly and last as long as possible.

This blog post will discuss four tips for maintaining your heavy machines. Following these tips can help you avoid costly repairs and keep your machines running smoothly for years to come!

Keep your machinery clean

One of the most important things you can do to prolong the life of your heavy machines is to keep them clean.

Dust and dirt can build up over time, causing parts to wear down and eventually break.

Make sure to regularly clean your machines inside and out to prevent this buildup.

One way to keep your machinery clean is by using compressed air. This method is especially effective for removing dust collected in hard-to-reach places.

Just be sure to use a low-pressure setting on the compressed air to not damage any delicate parts!

And after its consumption, you can earn when you sell equipment with a site like Boom & Bucket.

Lubricate moving parts

Another important maintenance tip is regularly lubricating all the moving parts on your heavy machinery. This will help reduce friction and wear, keeping components in good condition for longer.

There are a variety of lubricants available, so be sure to choose one that is compatible with the materials your machinery is made from.

Applying lubricant is usually relatively straightforward, but you should consult your machine’s manual before doing so. This will ensure that you use the right product and apply it accurately.

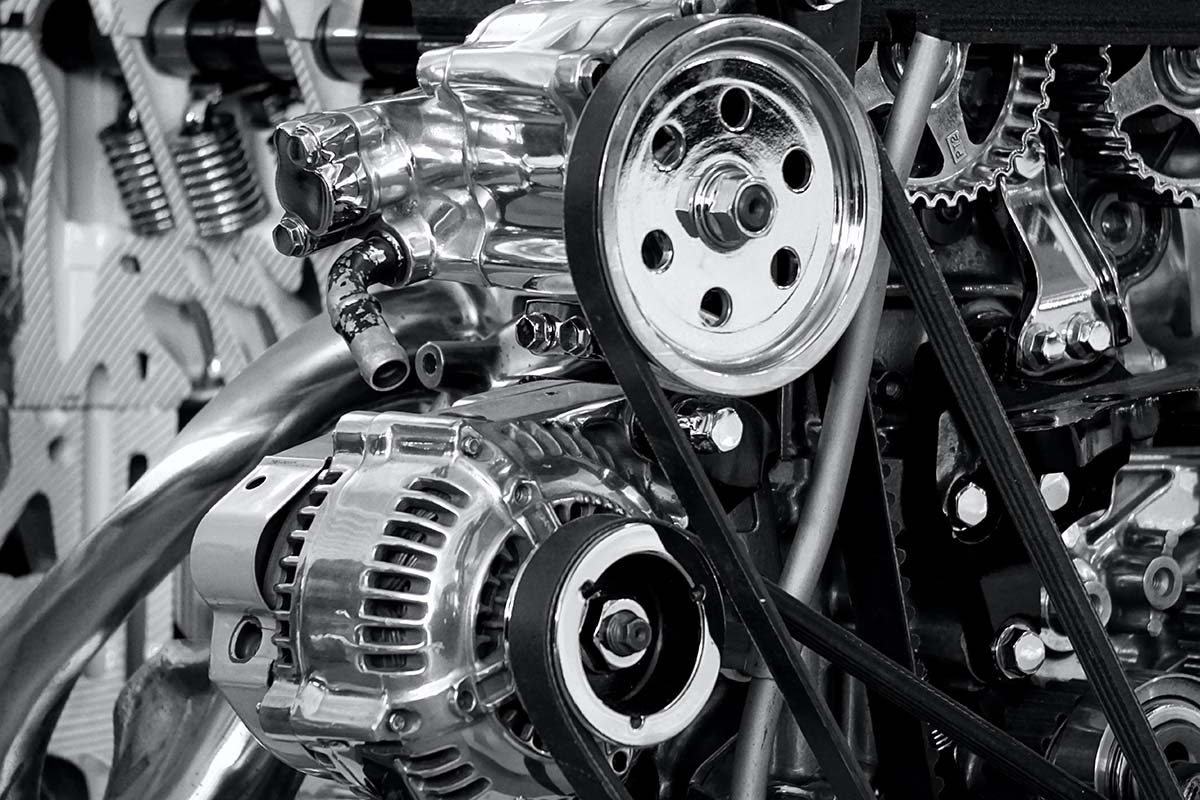

Inspect belts and chains

If your machinery has any belts or chains, it’s essential to inspect them regularly for signs of wear. These components can break suddenly if not correctly maintained, so it’s best to catch any issues early on.

Look for cracks, fraying, or excessive stretching when inspecting belts and chains. If you notice any damage, it’s crucial to replace the component as soon as possible.

This may seem like a minor repair, but it can save you from a much more costly breakdown. And if you find something doesn’t look right, do not hesitate to call professionals for new Caterpillar Engine Parts.

Keep an eye on fluids

Your machinery likely has several different fluids that need to be kept at the proper levels. These include engine oil, coolant, and hydraulic fluid.

Checking these levels regularly and topping them off as needed can help prevent significant issues from developing.

It’s also essential to ensure that these fluids are clean and debris-free. If you notice any contamination, it’s best to flush the system and start fresh with new juice.

These four tips can help you maintain your heavy machinery and extend its lifespan. Keeping your machines clean, lubricated, and properly serviced will go a long way towards keeping them in good condition.

If you have any concerns about the maintenance of your machinery, be sure to consult a professional.

They can help you troubleshoot any issues and keep your machines running smoothly for years to come!