Tired of the Warehouse Grind? These Machines Make a Real Difference

Key Points

- Less physical strain. The right machines take the pressure off your body—without slowing you down.

- More time for skilled tasks. Automating repetitive work frees you up to focus on what matters.

- A smarter, safer workflow. Better tools = fewer mistakes, fewer injuries, and a better work environment.

If you’re working in logistics or warehouse operations, you already know—some days just take more out of you than others.

And while the work gets done, it doesn’t always need to be done the hard way.

Modern warehouse technology isn’t just for big corporations—it’s made for real teams doing real work.

Machines that take on the repetitive, draining tasks and free you up to move, think, and operate better.

Let’s take a look at what’s actually helping on the ground—including some standout machines from Top Industries that are changing the way warehouses run.

Pallet Exchangers from Top Industries

If you’ve ever had to switch out a stack of loaded pallets quickly and safely, you know it’s not just another task—it’s a rhythm-breaker.

The pallet exchangers from Top Industries are designed to make that process smooth and hands-off.

These machines automate pallet transfers, reduce strain, and help operations move faster without extra steps.

They’re solid, reliable, and built with high-volume handling in mind.

Whether you’re dealing with wooden, plastic, or even damaged pallets, these systems step in where manual effort used to be the only option—and they do it without slowing you down.

Automated Guided Vehicles (AGVs)

Warehouse traffic builds up quickly. Forklifts zigzag, people push carts, and everything moves at once.

AGVs simplify that. These self-driving vehicles follow a set path through the space, handling material transport between stations while you stay focused on what’s next.

They’re steady, smart, and surprisingly helpful once integrated into the daily flow.

No need to chase them down. No interruptions. Just quiet, constant movement that keeps the floor productive.

Autonomous Mobile Robots (AMRs)

There’s always a stretch in the day when everything needs to happen at once. And that’s where AMRs really shine.

These robots move independently through the warehouse, adapting as things shift.

They help out where needed—sorting, picking, checking—without needing constant supervision.

Think of them as extra hands that are always available and never need a break.

And when they’re part of your routine, everything around them starts to run a little smoother.

Automatic Packaging Machines

As orders ramp up and deadlines close in, the packaging line gets tight. Time speeds up—and things need to go out right now.

That’s when automatic packaging machines become essential.

They pick, pack, seal, and label—fast and efficiently—so nothing piles up, and your shipments stay on track.

These machines adjust to different package sizes and handle the details without losing momentum. In a busy environment, that makes all the difference.

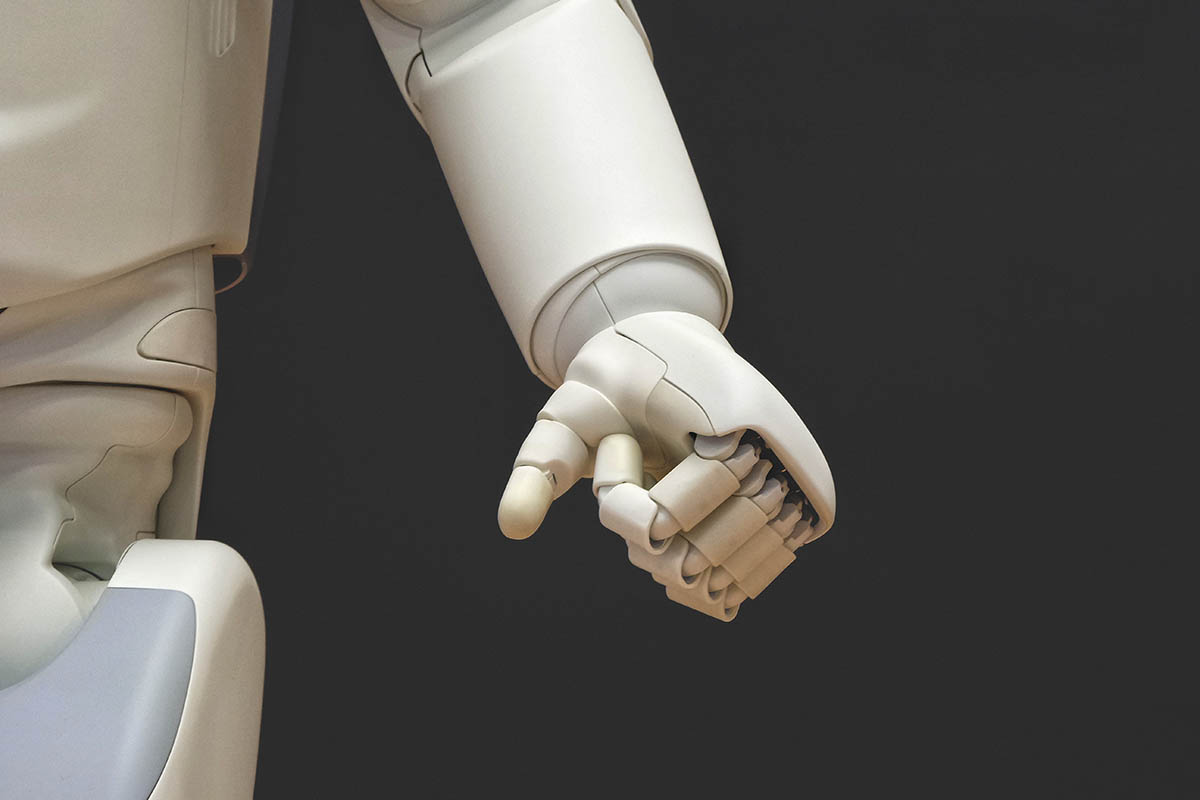

Robotic Arms: The Steady Hands That Never Stop

You’ve probably seen robotic arms in action before—on factory lines, in tech demos, maybe even in your own warehouse.

But what makes them so powerful is how quietly and consistently they get things done.

They’re built to lift, move, sort, and repeat with a level of precision that doesn’t slip—not after lunch, not at the end of a long shift.

With advanced sensors and smart programming, they do what needs to be done, the same way, every time.

In spaces where speed and accuracy matter (which, let’s be honest, is most of them), robotic arms keep things running smoothly.

No breaks, no burnout—just reliable output that helps the whole operation move forward.

For warehouses dealing with high-volume or detail-driven work, these machines aren’t just useful—they’re a solid, long-term part of the team.

Conveyor Belt Systems

A conveyor belt system is a classic yet highly effective warehousing tool.

These systems are used to transport goods and materials around a warehouse or production facility with ease.

By using conveyor belts, operations can run more smoothly and efficiently, reducing labor costs and improving turnaround times.

Conveyor belt systems come in various shapes and sizes, from overhead to floor-level systems designed to meet the needs of any operation.

They can be easily upgraded and customized to fit changing needs over time.

For lightweight or hygienic applications, such as in food production, flat flex belts can offer an ideal solution due to their open-mesh design, ease of cleaning, and excellent airflow.

Why More Warehouses Are Turning to Automation (And Why It Works)

Warehouses don’t look like they used to—and that’s a good thing.

Where there was once nonstop manual handling, long hours on repetitive tasks, and a lot of physical strain, automation has stepped in and changed the pace completely.

Let’s look at how it’s quietly reshaping the way things get done.

Lower Costs Without Cutting Corners

One of the biggest advantages of automation? Things just move faster—and more smoothly.

Systems like AGVs, AMRs, and conveyor belts are built to handle everyday tasks like transporting goods, sorting, and scanning with more precision and speed than anyone on the floor could keep up with. And because they run non-stop, there’s no overtime, no downtime, and fewer slowdowns.

Less time fixing errors. Fewer resources spent on repeat work. And no need to stretch your crew thin when things ramp up.

The result? A more efficient operation that saves money naturally—without cutting jobs or cutting quality.

Better Safety. Better Flow.

When machines step in to take care of the more physically intense or repetitive work, the whole floor changes.

You’ve got fewer people in tough positions, and more focus on oversight, coordination, and higher-value tasks. That naturally leads to fewer missteps, fewer close calls, and a smoother rhythm across shifts.

Automation doesn’t get tired or distracted. It doesn’t lose focus halfway through a job. That kind of consistency adds up—both in output and in the overall flow of operations.

And when everything moves safely and steadily, it’s easier to grow without the chaos.

Automation in warehouses isn’t about replacing people—it’s about building a better system around them.

One that supports the pace of modern business without pushing your team to the edge.

And that’s exactly what today’s best-run warehouses are starting to understand.

Increased Storage Capacity

Thanks to automation, warehouses can dramatically increase storage capacity. Automated systems like AS/RS (Automated Storage and Retrieval Systems) can store items in high-density configurations, maximizing the use of vertical space and significantly reducing the footprint required for storage.

This leads to more efficient use of space and the potential to house a larger inventory, ultimately increasing the scope of business operations.

Better Systems, Happier Customers

When things run smoother inside the warehouse, customers feel it on the outside.

Automation helps make that happen. With faster order processing, fewer mistakes, and reliable delivery timelines, customers get what they want—on time and exactly as expected.

And when that happens? They come back.

Tools like AGVs, AMRs, robotic arms, and conveyor systems aren’t just about efficiency—they quietly raise the bar for accuracy and consistency.

That means fewer returns, fewer complaints, and more positive experiences at every stage of the order.

It’s not just about speed. It’s about trust.

Automation gives businesses the breathing room to focus on what matters most: delivering high-quality products, building better relationships, and staying ahead of expectations.

And when your systems work smarter behind the scenes, your customers notice—even if they never see it.