How Reducing Back Pressure Unlocks More Diesel Horsepower

✨Key Points

- Reducing back pressure lets a diesel engine breathe easier and quickly boosts horsepower.

- Turbocharged diesels suffer when exhaust flow is restricted, causing lag, heat, and power loss.

- Upgrading exhaust systems cuts resistance, lowers EGTs, and improves overall engine efficiency.

Reducing back pressure is, without question, the core way to unlock serious horsepower and boost the overall efficiency of any diesel engine, especially in the modern, turbocharged trucks everyone drives today.

When you’re tuning for performance, the main objective is always getting the engine to breathe as easily as possible.

Getting rid of those restrictive parts lets the engine dump spent gases way faster.

By guaranteeing less restriction right behind the turbo, the engine runs much more efficiently and makes superior power—a result you almost always get by upgrading your vehicle’s diesel exhaust systems.

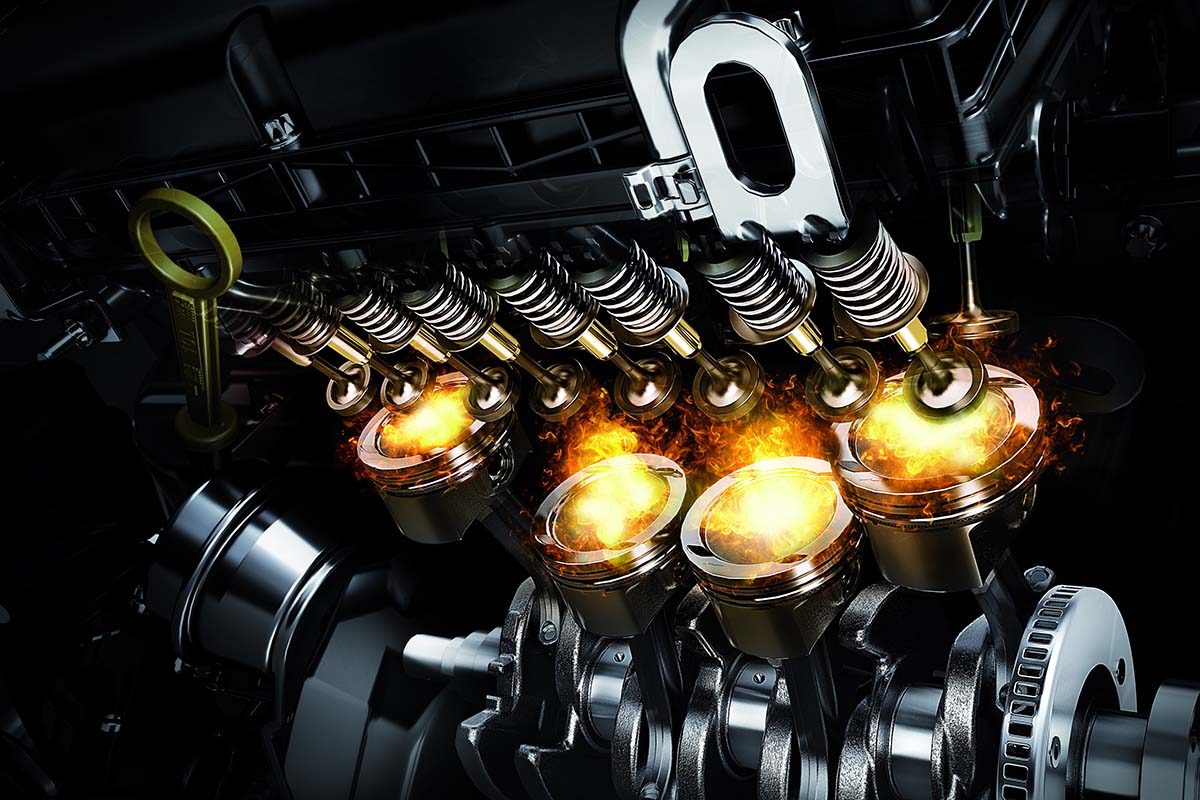

Understanding Back Pressure in Diesel Engines

Back pressure is basically just how much resistance the exhaust gases run into as they move from the combustion chamber, through the manifold, past the turbo, and out the back.

Sure, some older vehicles, especially non-turbo ones, need a little bit of back pressure to keep the gas moving, but turbocharged diesels work on a completely different system.

The Turbocharger’s Role

In a turbo setup, the energy from the exhaust gas is captured to spin a turbine wheel.

That wheel then drives a compressor that shoves pressurised air right into the engine.

Once the gas has done its work spinning the turbine, any kind of restriction put after that turbocharger turns into a real problem.

Too much back pressure causes three major performance headaches.

First, you get turbo lag.

That pressure right after the turbo actually chokes the flow, which drastically slows down the turbine’s spin speed.

Then there’s the issue of increased pumping losses—the engine wastes its own power trying to push against the resistance just to clear the exhaust gases.

That effort cuts directly into the final horsepower delivered to your wheels.

Worst of all, those trapped hot gases spike your Exhaust Gas Temperatures (EGTs), putting massive, dangerous heat stress on all your engine and turbo components, putting more heat stress on both the engine and the turbo parts.

Optimal Diameter and Flow

Modern performance systems use something called mandrel-bent tubing.

This keeps the pipe’s diameter exactly the same the whole way through, even when going around a corner.

That’s a huge difference from standard factory systems, which often use “crush-bent” pipes that seriously choke the flow in those corners.

Making the exhaust pipe bigger (usually jumping from the stock 3-inch to a 4-inch or 5-inch system) drastically cuts down the restriction right behind the turbo.

This is absolutely essential for maxing out the engine’s output, especially when you push the RPMs higher.

The Critical Relationship with the Turbo

The biggest power gains you get from cutting back pressure come from how much it actually helps the turbocharger itself.

When that restriction is lessened behind the turbo, the turbo can spin up faster and hold onto higher speeds with less effort.

This gives you two major perks:

- Faster Spooling: The turbo spools up quicker, which totally gets rid of that lag you feel when accelerating, delivering torque to your wheels much sooner.

- Lower EGTs: By dumping the hot exhaust gases quickly, the system reduces the heat stress on the turbo and the engine. This lets the engine run cooler and much safer, which is crucial when you’re dragging heavy stuff.

When EGTs are lower, tuners can safely put more fuel into the engine.

That directly translates into bigger horsepower and torque numbers without risking the engine’s long-term health.

The Role of Aftermarket Catalytic Converters

Federal and state laws mean you have to keep essential emissions parts like the Diesel Particulate Filter (DPF) and the Catalytic Converter (CAT).

High-performance systems built for today’s market come with high-flow catalytic converters.

These components are specifically engineered to have less dense internal cells, which means they clean up pollutants efficiently but still create way less airflow resistance than the parts the factory installs.

That means drivers get to stay legal without giving up the vital flow needed for peak performance.

Sound Management

A properly designed performance exhaust system totally changes the way your engine sounds.

By cutting back pressure and making the pipe bigger, the engine note usually turns deeper and throatier.

Manufacturers use specialized resonators and mufflers that are designed to target and cancel out annoying drone noises, all while keeping that aggressive, desirable sound of a powerful diesel engine.

Maximising Your Diesel’s Potential

Cutting back pressure is seriously the most important mechanical move you can make to unlock hidden horsepower and guarantee your turbocharged diesel is running at its absolute best.

It sets up a much better environment for the turbo to do its job, keeps those operating temperatures down (which can be dangerous when they spike), and frees the engine up to deliver power exactly where you need it: to the wheels.

Taking the Next Step in Performance

If you’re ready to make your diesel truck more responsive, powerful, and efficient for better towing or just your daily drive, go talk to a trusted performance shop that focuses on turbocharged diesel vehicles.

They can walk you through a mandrel-bent, high-flow component upgrade tailored perfectly to your truck’s specific year and model.