Advancements in 3D Printing Technology

The ability to quickly and cheaply produce brand new designs at the touch of a button makes 3D printing important for many commercial and research-based uses.

Plus, as technology continues to progress, more benefits are being recognized.

How 3D Printing Technology Has Advanced

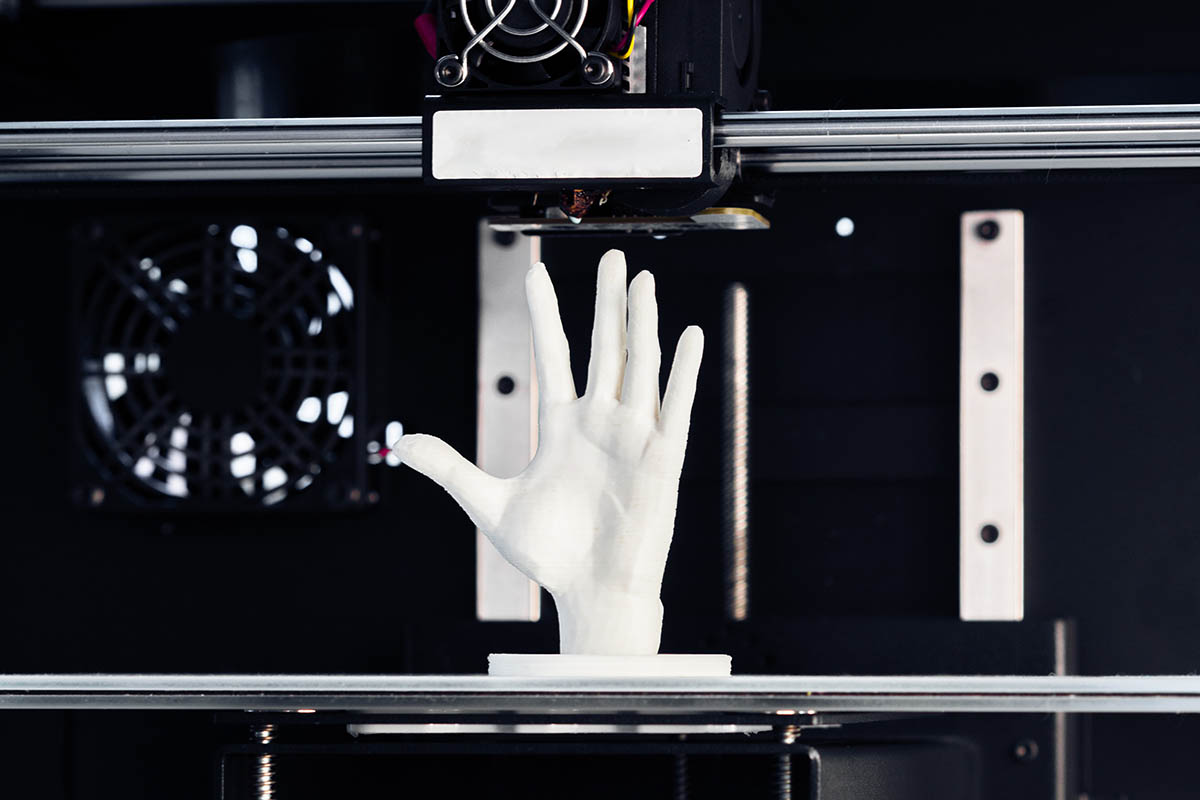

3D printing is currently one of the most exciting developments in manufacturing technology.

The ability to quickly produce new designs at the touch of a button makes commercial 3D printing important for many commercial and research-based uses.

As the technology continues to progress, the increased accuracy, associated cost efficiency, and inherent speed make it a fundamental consideration for all development processes.

Before you proceed, check the 3D printing guide that is narrow in focus.

Xometry’s Complete 3D Printing Guide provides a wealth of comprehensive knowledge, from how to get started to post-processing options, and everything in between.

Increased accessibility

There was a time where 3D printing was only possible for a select few.

3D printers themselves were expensive, and to operate one, you would need to employ someone with the specific training.

However, 3D printing technology has advanced to the stage where everyone can use a 3D printer.

Like the 3D printing pen, new developments make this tech, so simple to use it has become more toy than a tool.

As a sign of the increased popularity, there are even categorized awards to recognize their creative capabilities.

Mail-order 3D printing

As its popularity has grown, more companies have started offering cheap, efficient alternatives to buying your own 3D printer and employing the staff to operate it.

The most common use of commercial 3D printing is the small-scale manufacturing of new product designs.

Rapid prototyping services allow you to order singular prototypes for a fast assessment of functionality and suitability.

All you have to do is send in your designs, and you will receive the finished printed design by post.

More robust materials

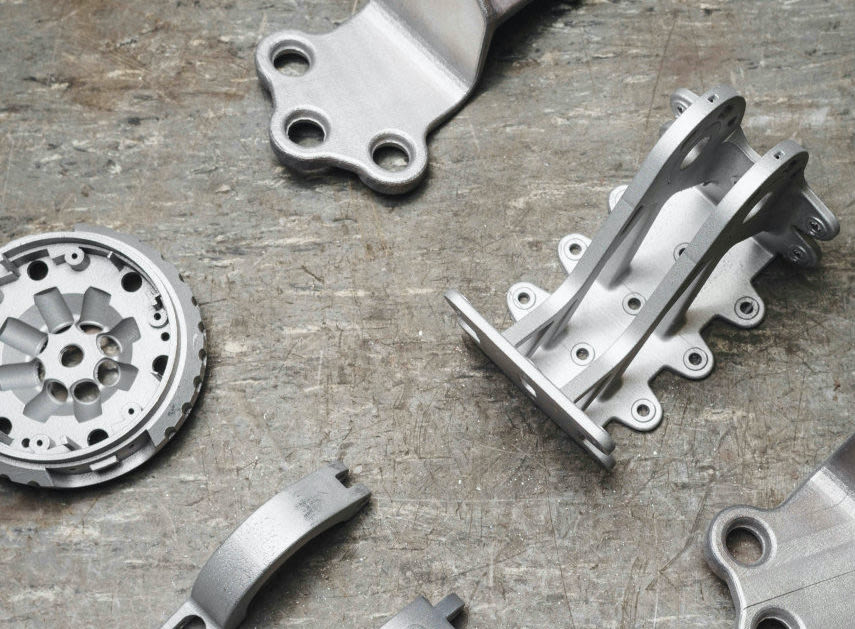

In the beginning, 3D printing was focused only on printing designs in plastic.

However, as things developed, the printers have been adapted to print different materials.

Metal 3D printing is now possible in a few different ways.

Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) are both forms of metal 3D printing that rely on lasers to melt the metal and stick it together.

In DMLS, the metal used is actually an alloy, and in SLM, the metal is all one type.

3D printing in metal allows for easier manufacturing of small custom parts.

It can be optimized to perform better with a lower weight and less material used. The process allows super-alloy metals that were too difficult to work with under older manufacturing methods.

As 3D printing technology progresses, there are additional benefits to manufacturing.

Less harmful emissions – so less environmental impact – mean that 3D printing has quickly become the technology to watch in 2020.