Importance and Types of Laser Marking

Business Marking systems or engraving systems give the final touch to a product but also an important one. Many of the products that we use today are recognized by the logos or symbols etched on their surfaces and without engraving machines, it is hard to imagine how these brands would survive the competition and stand out.

Wood, metal, plastic, rubber, polythene, glass… there are many surfaces on which a marking machine must be capable to mark on and many characters like alphabets, numbers, symbols, barcodes, 2D data matrix codes, and graphics which it should be capable of marking on the chosen surface.

Be it a logo or a company symbol, product number, or barcode information, the markings could be anything that states the important mentionable. Broadly, there are two types of industrial engraving systems namely, contact and non-contact engraving machines.

However, with improved research and technology, industries have come to terms with non-contact marking machines which are more accurate, precise and make crystal clear marks when compared to the former.

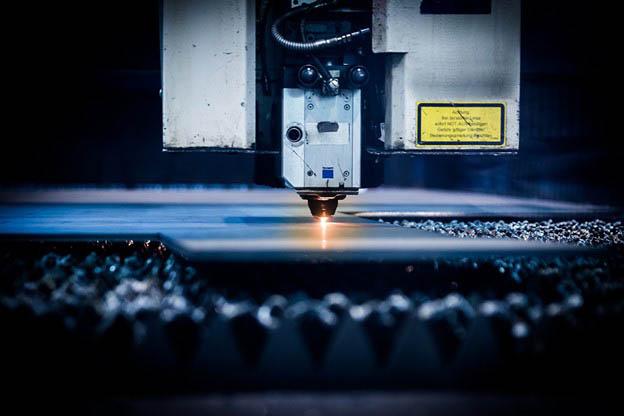

Laser engraving machines are the most popular among these non-contact marking machines and there are many reasons why industries agree that laser marking on plastic engraving systems is indeed the best.

Here are a few advantages/importance of using laser engraving machines to mark on industrial products of varied interests and concerns.

Their marks are crystal clear

Precise and enhanced when compared to marks made by other marking systems.

Laser marks

More durable when compared to others, capable of withstanding harsh industrial conditions, insensitive weather conditions, and rough usage.

Since laser marks are more enhanced and durable

They add value to the product they adorn, leading to increased customer satisfaction. Types of Laser Engraving Machines There are many types and subtypes of laser engraving machines.

However, we are going to discuss the most popular laser marking systems amongst these, Fiber laser marking systems and CO2 laser marking systems.

Fiber Laser Engraving Machines

These are designed to mainly mark metallic surfaces like iron, stainless steel, aluminum etc., and are intended to be operated in industrial environments prone to dust, vibration, and shock.

Fiber laser marking systems deliver a high-power laser beam directly to the marking head using a metal-sheathed fiber cable.

These machines are available in a variety of subtypes, classified on their output power and marking depth. The engraving machines are compact and modular in nature and offer enhanced accuracy and clarity in their markings.

CO2 Laser Engraving Machines

These are designed to mainly mark non-metallic surfaces like glass, plastic, wood, rubber, etc. They use a carbon dioxide-filled laser tube to generate a laser beam of high power and thus fall under the category of gas lasers.

CO2 laser marking machines are intended for industries that demand high-precision and accurate markings. Again, these machines are of many subtypes, classified on the basis of their output power and marking depth.

LASIT is a company that develops laser marking on plastic and engraving technologies and does so with passion and dedication.

LASIT is big enough to make a difference but small enough to take care of every single customer.

LASIT Study and Design team ensures traceability, production chain control, brand visibility, and industrial process automation.