Why do Businesses Need to Make the Most of Nitrogen Generation Benefits?

Did you know that nitrogen makes up the majority of the air we breathe? All living things require oxygen to survive, but air contains 78% nitrogen, only 21% oxygen, and other gases’ trace quantities. While the human body does not use nitrogen, it is beneficial in a variety of industrial applications.

Stated, an infinite supply of nitrogen is readily available, enabling you to achieve the necessary purity at a fraction of your current annual nitrogen cost if you adopt on-site nitrogen generation.

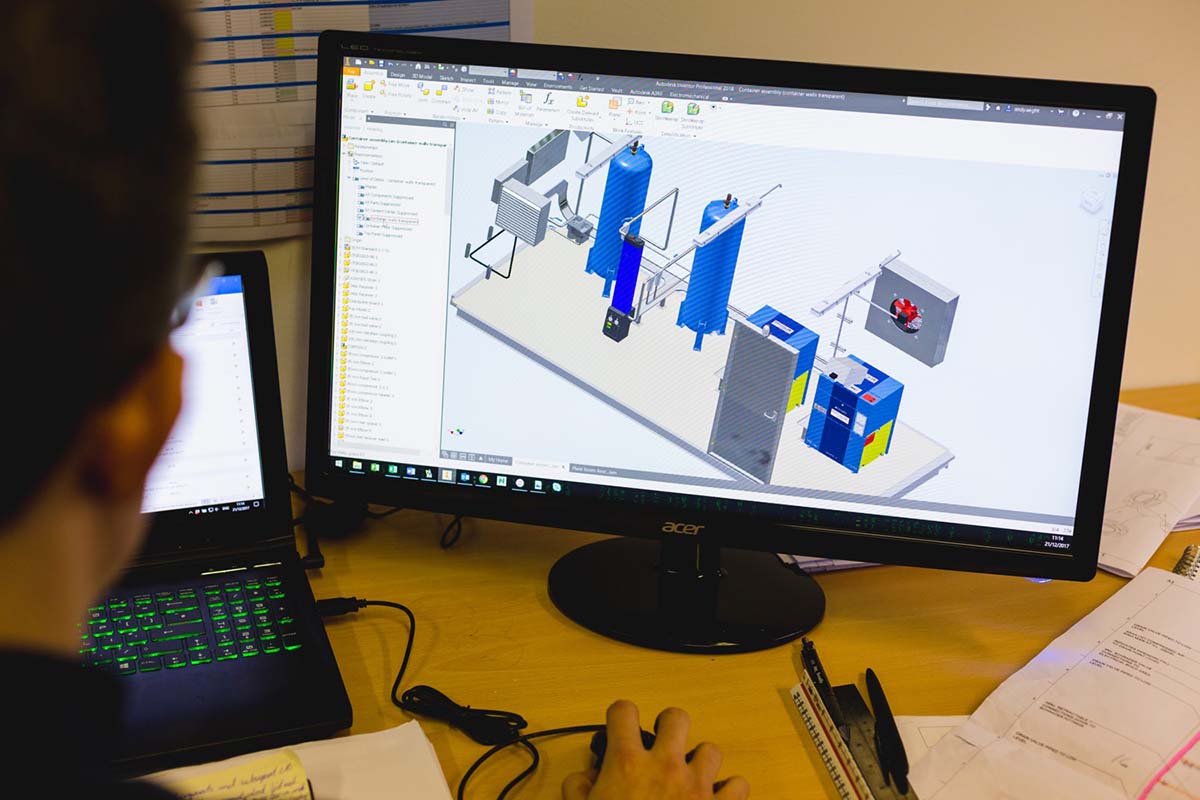

Nitrogen generation allows you to remove nitrogen molecules from dry compressed air and pure output nitrogen. Nitrogen generators can produce purity levels as high as 99.9999%. This is beneficial because on-site nitrogen generation eliminates the need for buying gas cylinders and all other related costs while still supplying nitrogen on demand.

How Does On-site Nitrogen Generation Work?

Compared to bringing in nitrogen tanks and bottles, onsite nitrogen generation has five distinct advantages: lower total cost, no wait time, guaranteed purity, improved safety, and environmental friendliness. There are two main types of nitrogen generators, and these are how they work:

Membrane Generators

Membrane Technology separates oxygen from a dry compressed air stream using hundreds of thousands of hollow, polymeric fibers, each the human hair’s diameter, to create gaseous nitrogen. The purity of nitrogen (O2 Content) can be adjusted by changing the amount of air passing through the membrane. Membrane modules can be added as needed, making scaling up as requirements change easy.

Pressure Swing Adsorption Generators

PSA technology consists of two carbon molecular sieve (CMS) towers. From the bottom of the “on-line” tower, compressed air flows up through the CMS. The CMS adsorbs oxygen and other trace gases preferentially, allowing nitrogen to pass through. The online tower switches to regenerative mode after a fixed period, venting contaminants from the CMS.

Why Should You Switch To On-site Nitrogen Generation?

The vast majority of manufacturers have their nitrogen gas delivered in bulk. However, being self-sufficient and producing your nitrogen gas with an on-site nitrogen generator is a safer, more sustainable alternative. This reduces the ongoing costs of bulk delivery and storage and makes the process much safer.

If a company does not produce its nitrogen, it can get it from cylinders, dewars, or bulk liquid tanks. Aside from the added costs of getting these supplies supplied versus on-site nitrogen generation, each method has its own set of costs and safety concerns.

Problems With Bulk Nitrogen Supply: Safety

When moving high-pressure cylinders to and from storage, they must be monitored closely because they are extremely dangerous if knocked over or mishandled. The cylinders are heavy even when empty and can cause injury if they fall. Furthermore, if not done correctly, changing high-pressure lines can be dangerous, and turning them on when lines are not properly secured can result in explosive results.

Wastage

Due to rapidly dropping pressures and the accumulation of impurities, it is physically challenging to extract every cubic foot of gas from a cylinder. When a company returns “empty” cylinders to a gas company, it essentially returns about 10% of the gas. With Dewar usage, off-gassing – an issue common with gaseous, liquid storage – occurs when liquid nitrogen is continuously converted to gas and leaks out. As a result, if a business does not use its supply regularly, it will eventually be lost.

Nitrogen Generation Benefits: Installation/Rental Costs

Many gas companies also charge for the rental of cylinders or tanks. Businesses should be mindful that a gas supplier’s invoice might contain a slew of unexpected charges, such as cylinder rental, that were not anticipated.

Suppose you use bulk tanks, which are massive and must be mounted outside the facility, necessitating a significant amount of room. There will be recurring fees for equipment leasing and upkeep in addition to the installation costs. Finally, bulk shipping charges can apply depending on the scope of a company’s requirements.

Product Damage/Loss

Products can be damaged, often beyond repair, if operators do not track gas supply levels and fail to move tanks in the middle of a run or even continue running without gas. This is a significant liability that often necessitates the installation of external control systems. Failure to keep track of gas supply levels will cost a lot of money.

Logistics

Suppose a company operates in a remote region or outside of the gas supplier’s main route. In that case, it may be impacted by problems such as delayed production or having to turn down the new business entirely due to untimely supply.

Nitrogen Generation Benefits: Final Thoughts

Nitrogen generators contribute to sustainability by requiring less energy to operate, long service life, and reducing CO2 emissions. As a result, on-site nitrogen generation units’ cost savings and long-term sustainability are key factors driving their adoption in various industries like refineries, chemical, electronics assembly, oil & gas processing, food & beverage, and others.