Precision Injection Molding Techniques For Plastics Manufacturers

The precision injection molding process is characterized by dimensional tolerance, tightness of mold dimensions, and shrinkage fluctuations. When the product is made of plastic, the mold should be accurate and precise.

It should also be equipped with a water line to compensate for heat loss in the plastic during the injection process. The correct equipment can be critical to achieving the desired results. In addition to quality molds, precision injection molding requires several other factors.

The plastic material used for a precision-molded part is critical. The type of plastic resin used determines the quality of the molded product. Other criteria related to precision molded parts include the shrinkage range of a parker hose of the plastic.

A smaller shrinkage range provides a tighter tolerance range and can be suitable for products whose size is not exact. However, obtaining tight tolerance levels with a broader shrinkage range can be challenging.

Selecting the materials for a precision plastic mold

When it comes to selecting the materials for a precision plastic mold, the overall structure of the mold is crucial. It is the embodiment of the final product. It includes the ejection system, gate system, and water transportation system. In addition, the structure must allow for the post-processing orientation of the product. The overall design of a precision plastic mold should also ensure that the result is high quality and accurate.

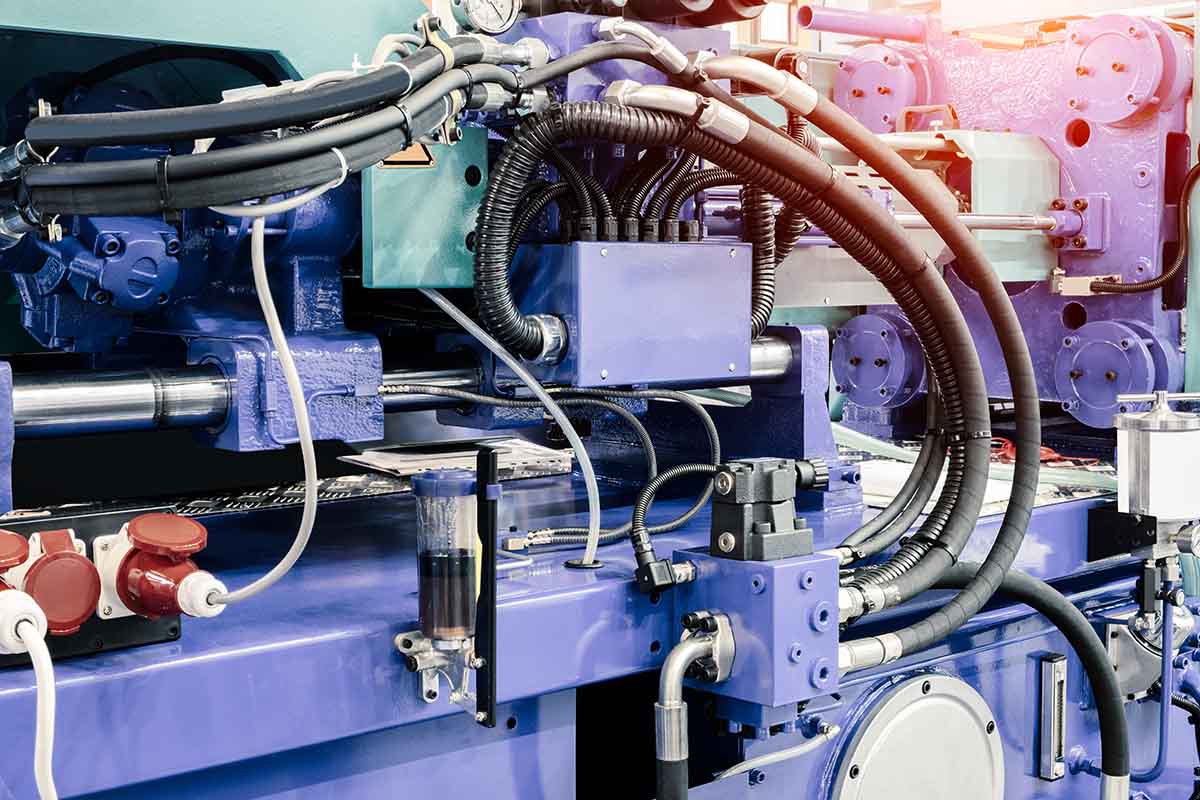

The mold must be rigid and offer high clamping precision for a precision mold. This is the ability to repeat the clamping force. It also requires accurate control of variables. The molding process should include multistage or stepless injection to ensure reproducibility in shape and size. On the other hand, a high temperature increases the amount of shrinkage, and a lower one increases the amount of shrinkage. When this is achieved, the plastic part can be high quality, high-value product.

The accuracy of the finished product is the most important technical indicator of its quality. It refers to dimensional tolerances, geometric tolerances, and surface smoothness. Injection molding of precision plastic products requires strict control of 4 factors: the material, the mold design, and the operator’s technology level. When these factors are optimized, the result will be a high-quality, accurate plastic product. When these factors are perfect, the process will be repeatable and flawless.

Injection precision

Injection precision is the most crucial factor in precision in manufacturing. For example, a high-quality mold will be made of plastic as close to the original as possible. By ensuring that the product is manufactured to the highest standard, a company can ensure that it will maintain high-quality standards throughout the manufacturing process. A machine that can produce products at a high-quality level is the key to success in the plastic industry.

Mold precision is dependent on the accuracy of the cavity and the parting surfaces of the mold. The precision of a mold is highly reliant on the environment and temperature control. The environmental temperature variation is the primary cause of deformation in plastic products. Moreover, the environment has a significant effect on the mechanical strength of a precision product. Its dimensional accuracy is also affected by the environment. As the temperature in the mold increases, the mechanical strength of the part increases.

Precision injection molding requires a high-quality plastic mold that is easy to mold and eject with a smooth surface. The process also allows a user to add specialty coatings to the product. Once the part is completed, it is only necessary to remove the excess plastic around the channels. Some of the thermoplastics used in precision injection molding include polyethylene, which is versatile and affordable. It is also waterproof and resistant to microbial growth.

The precision of a precision injection mold depends on several factors, including its dimensional tolerance and the size of the mold cavity. The size and shape of the mold cavity are crucial for a precise result. It must be accurate enough to ensure the dimensional accuracy of the parts. The machine must also have a fast hydraulic system to meet the customer’s demands. Injection molding is an excellent mass production process. Therefore, the cost per molding of the products is highly competitive.